Nanotechnology fabrics

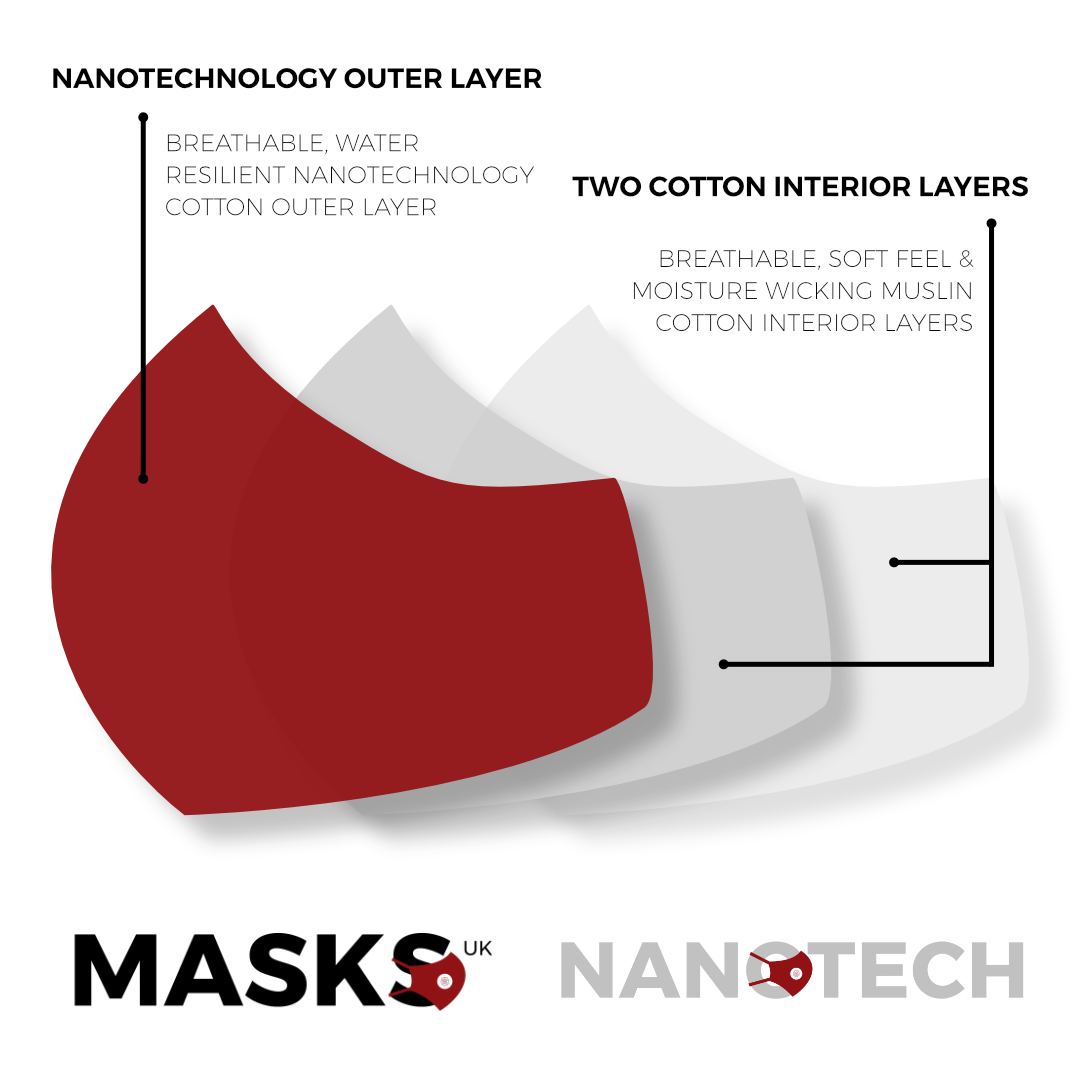

Nanotechnology fabrics are fabrics specifically manufactured to have special qualities like hydrophobicity, water-resistance and high durability. These enduring characteristics are created by weaving nanofibers (nano-whiskers) that have certain properties and by adding nanoparticles that can provide traits such as bacterial resistance and the “lotus plant” effect, which creates resistance to dirt and water. Nanotechnology fabrics have many potential applications beyond just clothing, they are used in bioengineering, electrical engineering and computer science to name but a few industries. This is the technology we have used in our 3 layer nanotechnology cotton masks. They also have the possibility to completely transform the textile industry.

Nanotech fabrics are produced using a varied number of different procedures. One of these processes is the immersion of the fabric into a specialist sol-gel used to deposit nanoparticles (nano-whiskers) into the material. Some important and useful applications for nanotechnology fabrics include wrinkle and stain-resistant clothing and antimicrobial clothing for hospitals.

How does nanotechnology improve fabrics?

Making composite fabric with nano-sized particles or fibres allows improvement of fabric properties without a significant increase in weight, thickness, or stiffness as might have been the case with previously used weaving techniques. For example, incorporating nano-whiskers into fabric used to make pants produces a lightweight water and stain repellent material.

So, what is Nanotech Fabric?

A fibre that has a width of less than 1000 nanometres (1000 nm or 1 μm) is generally defined as a nanofiber. A nanoparticle is defined as a small group of atoms or molecules with a radius of less than 100 nanometres (100 nm). Particles on the nanoscale have a very high surface area to volume ratio, whereas this ratio is much lower for objects on the macroscopic scale. A high relative surface area means that a large proportion of a particle’s mass exists on its surface, so nanofibers and nanoparticles show a greater level of interaction with other materials. The high surface area to volume ratio observed in very small particles is what makes it possible to create many special properties exhibited by nanotech fabric.

The use of nanoparticles and nanofibers to produce specialized nanotech fabrics became a subject of interest after the sol-gel and electrospinning techniques were fully developed in the 1980s. Since 2000, dramatic increases in global funding have accelerated research efforts in nanotechnology, including nanotech fabrics research.

What is the Sol-gel process?

The sol-gel process is used to create gel-like solutions which can be applied to textiles as a liquid finish to create nanotech fabrics with novel properties. The process begins with dissolving nanoparticles in a liquid solvent (often an alcohol). Once dissolved, several chemical reactions take place that cause the nanoparticles to grow and establish a network throughout the liquid. The network transforms the solution into a colloid (a suspension of solid particles in a liquid) with a gelatinous texture. Finally, the colloid must go through a drying process to remove excess solvent from the mixture before it can be used to treat fabrics. The sol-gel process is used in a similar fashion to make polymer nanofibers, which are long, ultra-thin chains of proteins bonded together.

Textile Manufacturing & Nanoengineered Coatings

When nanoengineered coatings are applied to fabrics, the nanoparticles readily form bonds with the fibres of the material. The high surface area relative to the volume of particles increases their chemical reactivity, allowing them to stick to materials more permanently. Fabrics treated with nanoparticle coatings during manufacturing produce materials that kill bacteria, eliminate moisture and odour, and prevent static electricity. Polymer nanofiber coatings applied to textiles bond to the material at one end of the polymer, forming a surface of tiny, hair-like structures. The polymer “hairs” create a thin layer that prevents liquids from contacting the actual fabric. Nanotech fabrics with dirt-proof, waterproof, stain-proof, and superhydrophobic properties are results of the layer formed by polymer nanofibers.

MASKSUK

Our response to the Coronavirus COVID-19 Pandemic, the 3 Layer Nanotech Coated Cotton Mask.

Due to our existing company operations, we have direct access to staff, machinery, logistics and most importantly the Nanotech fabric. Having this at our fingertips we felt we needed to do something to help the worldwide issues. We want to support our medical staff by offering alternatives to the public, thus easing the global shortage that is currently an issue for medical services, by offering a high-quality alternative. We also have a duty of care to help our staff stay employed, pay their bills and feed their families, and whilst we will make a minimal profit, we can be active in helping to slow the spread of the disease in this worldwide pandemic.

Recent Comments